The Revolution in the Digitalization of Analog Measuring Instruments

Many are faced with the problem of how to integrate their tried and tested but outdated machines into a modern, data-driven environment without having to make massive investments in new equipment. As part of our

InnovateSAP

initiative, we have developed a groundbreaking solution based on the use of artificial intelligence to automatically read analog data displays.

The Challenge

The challenge is to introduce existing analog machines that have done reliable work for decades into the digital world. In particular, analogue measuring devices, which are indispensable for the collection of critical data, face integration problems into modern digital infrastructures.

Our solution

Our solution at HO2 combines advanced AI techniques with the use of live camera data directed at these analog devices. Here, the live feed is analyzed by our AI, the data from the analog measuring devices is recorded and converted into digital formats. This innovative approach not only reduces costs, but also significantly minimizes the manual workload of employees.

From idea to implementation

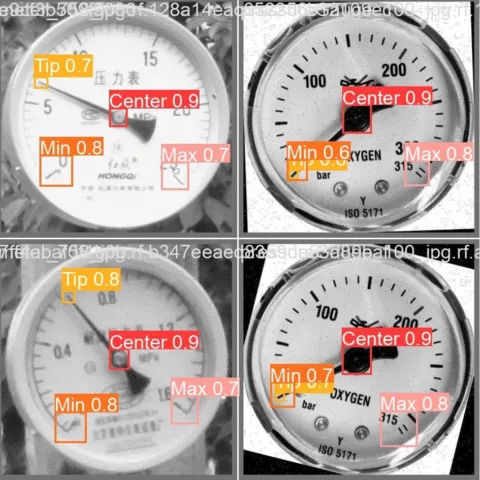

Our approach was innovative and practice-oriented at the same time. We used a pre-existing model for recognizing things in imagery as a starting point. The architecture of the model has been adapted and specially trained for the detection and evaluation of dial gauges. Providing the data as a residual service enables the AI to seamlessly process the live data directly from the camera. We then store the transferred data in a database from where we can access this data for analytical or security purposes.

Results and outlook

The results are promising. By implementing our solution, companies can continue to use their proven machines while reaping the benefits of digitalization. This approach is not limited to complex machines, but can also be extended to simpler applications, such as monitoring pipelines using AI to collect pressure and flow data.

Here are some example results with the detected characteristics (minimum, tip, center, maximum) from which the current meter reading can be determined:

The possibilities are manifold and extend far beyond pure machine integration. With our InnovateSAP initiative, we offer companies the opportunity to transform their analogue dilemma into a digital solution and successfully lead their production into the digital age.

If you’re ready to take the next step towards digitizing your production, contact us today. At HO2, we’re here to guide you through this change and future-proof your operations.